Cost Control Of Steel Strucure Projects

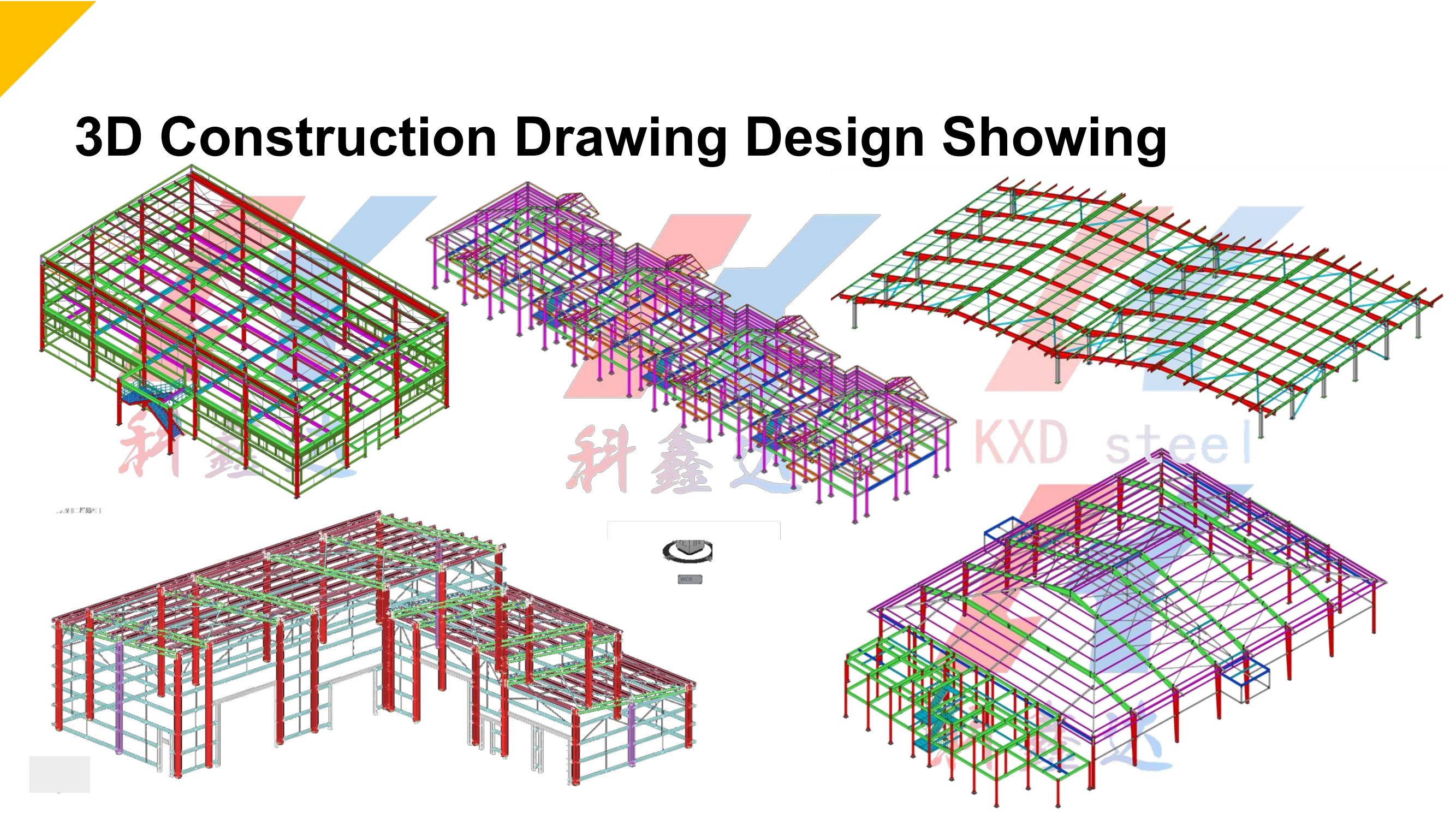

The construction steps of steel structure projects is planning, design, construction, and acceptance. Among these four stages, the design stage is the key.

When architects design a building structure, different formulas have different choices of building materials, which will have a great impact on the project cost. Such as the choice of foundation type, the determination of room structure layout, the determination of floor height and number of floors, etc. Next I will give an example of the main structure system.

Foundation: Choose a reasonable foundation type and control the section size and depth of the foundation.

This plays an important role in controlling the cost of the entire steel structure project.

Column: The column grid layout is the basis for determining the column span and the distance between two adjacent columns in each row.

Normally the column network size is between 6-12m. The column space is small, the force transmission route is short, the upper structure saves materials. But the basic cost may be higher, so whether the column network layout is reasonable has a great impact on the structure cost of the project . In addition, the choice of column cross-sectional shape and size also directly affects the project cost.

Beam: The rectangular section of the beam is a common bending member, which is often used in design. But its material utilization rate is very low.

Bolt connection is with simple construction process, convenient installation. So it is especially suitable for site installation and connection.

However, the bolt connection needs to make holes on the components, which raises the technological requirements of the processing factory and also increases the workload. Due to the openings, the cross-section of the component is weakened to a certain extent, and the connected plates need to be overlapped with each other or connected pieces such as splicing pieces are additionally provided. Therefore, it need more steel materials than welding connection.

However, on-site welding has higher requirements for both the construction environment and the construction personnel. High-altitude operation also increases the difficulty and danger of on-site welding. Therefore, bolt connection has gradually become a popular installation method for steel structures.