Qingdao KXD Steel Structure Co., Ltd, is one of the largest

manufacturers of steel buildings, specialized design and

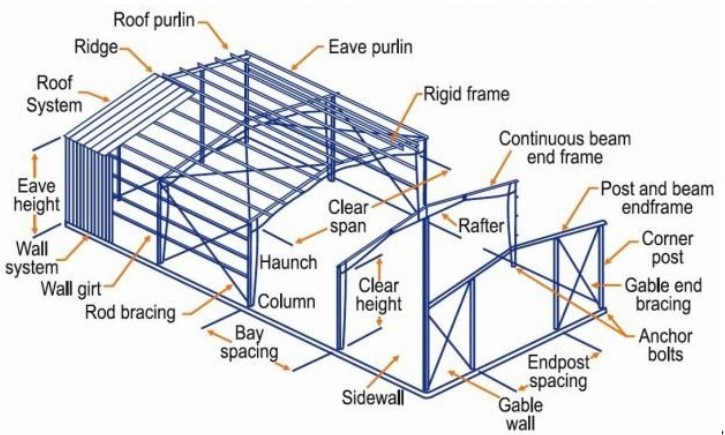

manufacturer for pre-engineered/fabricated steel buildings and

specialized architectural/structures in China with capacity over

10000 tons monthly and having state of the art manufacturing

facility with laser and robotic machines in our 3 production units.

In a bid to render our clients with impeccable products and

services, our company has acquired CE certification (EN1090

certificate), ISO 9001, ISO140001, ISO45001 Certificate and WPQR

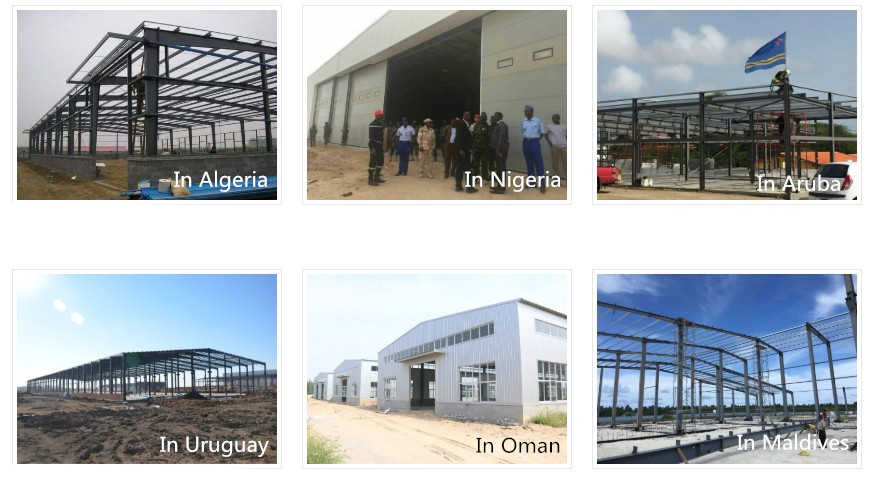

for anticipated apprasal from our clients. Our footprints shall be

witnessed in a large number of countries and regions such as

Canada, Australia, Peru, Sri Lanka, France, Brazil, England,

America, Ethiopia, Algeria, etc., that is to say, more than 130

countries around over the world.

What attaches great importance to the success of a steel building

company is a solid design and engineering team. At KXD, you

shall witness more than 50 members of designers, architects,

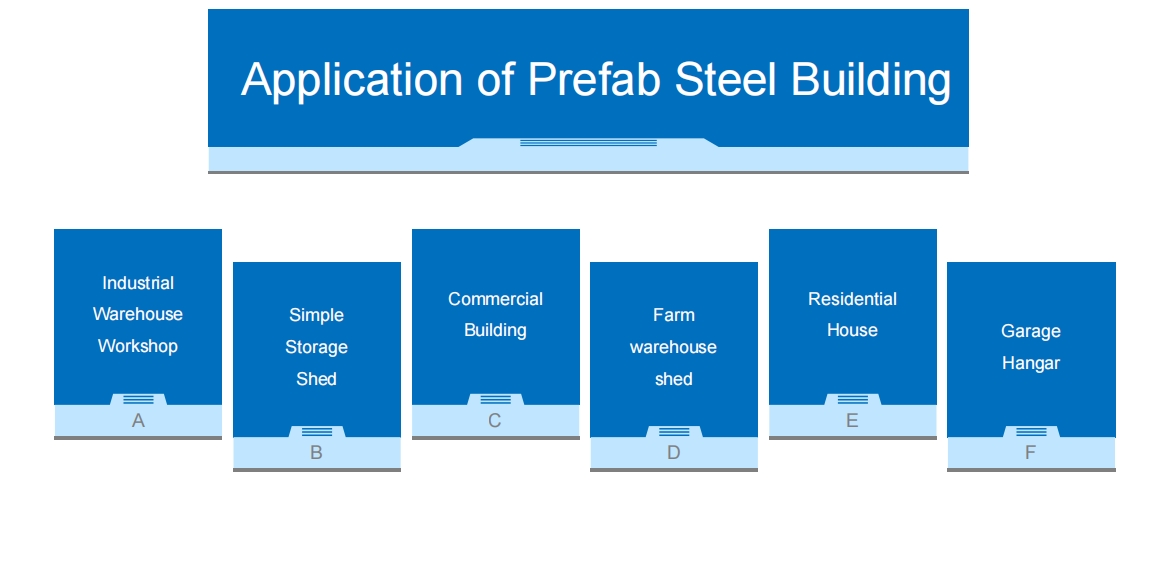

detailers, consultants etc. KXD is destined to offer tailed and

reliable design and engineering services to each of our customer

whether for industrial, commercial or agricultural property

developments.

Based on the moto of Trustyworthiness, Professionalism,

Cooperation, Mutual benefits, our company is building a

comprehensive industrial chain system gradually and making great

efforts to supply our quality products and perfect after-sales

services to worldwide clients. Our goal is to be a household name

in the steel building industry.